Strategically Embracing the Automation Transition

Automation can improve manufacturing in many ways, from increased efficiency, to greater worker safety, to more seamless equipment design. It can even help bridge generational transitions in family businesses and preserve expertise built over years of hard work. However, automation comes with many questions as well. How quickly can technology be implemented? How long will it take workers to learn how to use it effectively? Answering these questions in a way that makes sense for your business is critical.

Software and hardware both matter

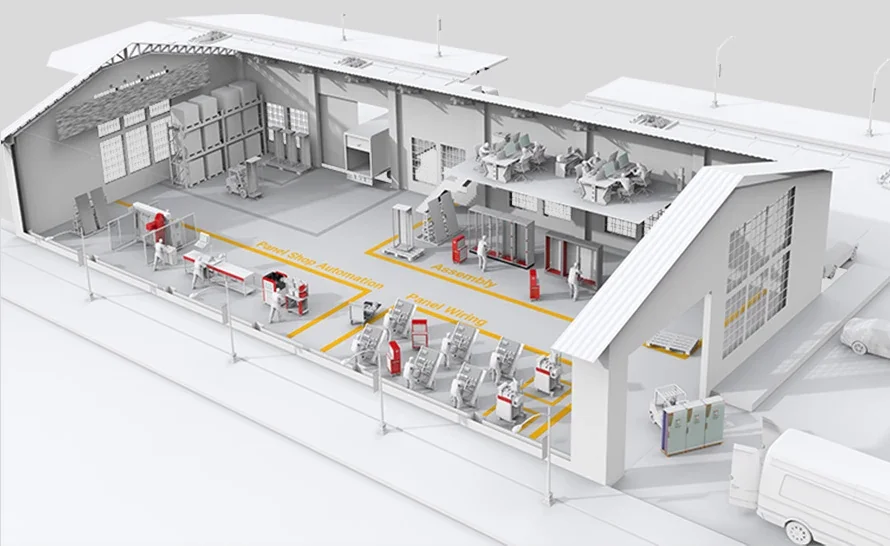

Based on customers in the industrial sector, estimated per-wire times for design, processing and assembly for a project can be as high as 12 minutes per wire. If you have some process and wire processing, this number can be reduced significantly. The complete adoption of automation can lead to major time savings. The best automated panel shops are using software to design products and then seamlessly integrating those designs with humans and automation machines on the panel shop floor.

For design software to be useful, it needs to take into account how a given panel will be built in real life by considering things that come after the design process: how do we lay out a panel so that it can be easily assembled? How can our design processes provide clear instructions for both people and automation programs? If design software allows or encourages engineers to design schematics that cannot actually be assembled easily on the shop floor, it is for all intents and purposes just a suggestion. That is not a good use of engineering or manufacturing time. The best design software will allow designing in both 2D and 3D and reference detailed enough information about parts to prevent difficult-or-impossible-to-assemble schematics from getting to the shop floor in the first place.

Where to begin?

For manufacturers that have not yet implemented automation solutions, it can be difficult to decide where to start. If you’re not ready to make a full leap into automation, deciding whether to start with software or hardware can sometimes feel like deciding between buying a car and buying gas. Do you buy an expensive piece of machinery without the software to fully take advantage of it? Or do you buy design software without the machines to build product? Do you buy a car and push it or do you buy gas without anything to fuel?

To shift your thinking, it might be helpful to think of automation equipment as an electric car and design software as electricity. Using this analogy points us towards starting with design software, which can help engineers complete schematics faster and with reduced errors. Even if you don’t have an electric car yet, you can still use electricity. Then you could bring in a small automation machine, and once the incremental returns begin to come in from that machine, continue adding on to the system until you are ready to fully optimize your manufacturing processes with automation.

Managing Change

No matter how strong of an implementation plan you have for automation, change is hard. Bringing automation into manufacturing requires a shift in approach over time; it is not possible to instantly flip the switch. In addition to starting with small projects, it can be helpful to designate a few automation champions among engineering and manufacturing staff that are particularly excited about learning new technologies. These people can help find the best way to implement automation solutions and serve as advocates for technology among the rest of the workforce.

Along with adjusting to change, an issue that comes along with adoption is forgetting to consider training and implementation services as a key factor of success. Full process changes takes time, commitment and the proper resources. Companies that value and invest in sound implementation are much more likely to be successful.

One of the biggest mistakes that people make when implementing factory automation is not committing, or not giving things enough time to develop. People often expect automated tools to immediately automate every process and create an output that is exactly the same as what they used to build manually, and these expectations can set manufacturers up to fail. There will be roadblocks in the transformation process. Manufacturers adopting automation solutions cannot expect their lives to change overnight. The right mindset is one of constant change agility; thinking about design, thinking about production and finding ways to improve efficiency and performance. That is the ultimate goal of automation, not a direct replication of previous processes with less human interaction.

Around the world, nVent is bringing its deep application expertise and broad solutions portfolio to help customers do business more efficiently and with better results. Learn more about our end-to-end automation solutions here: DTM Software | nVent HOFFMAN

About the Author:

Sanu Warrier - Product Director

Sanu Warrier is Product Director for nVent, leading the global deployment of electrical design solutions. As part of the design to manufacturing platform, his work focuses on empowering customers eliminate inefficiencies, improve design processes, and reduce costs to enhance competitive advantages.

You may also be interested in:

Taking Control of Electrical Design with DTM Software | nVent →

How Modern Automation Technology Helps Bridge Generational Gaps | nVent →