Addressing Military Electronics Cooling Challenges with AI

With advancements in military electronics and the push for reduced size, weight, and power (SWaP), cooling solutions have become increasingly vital. Artificial intelligence (AI) is now a key player in this transformation, influencing both the demands and the solutions for thermal management.

Leading defense suppliers such as BAE, Lockheed Martin, and Thales are integrating AI into electronic warfare (EW) systems, applying it to autonomous platforms, mission planning, geospatial intelligence, and radar. These AI-driven systems require significantly more processing power, which in turn generates higher thermal loads. Ensuring optimal cooling is essential to maintain performance and reliability in mission-critical operations.

Intelligent Thermal Management

Traditional EW electronics are typically designed for specific functions—communication, intelligence, targeting—and rely on limited inputs to produce narrow outputs. These systems use relatively little processing power and require minimal cooling. However, AI-enabled systems must process vast datasets and perform complex analyses, demanding more robust thermal solutions.

As processing speeds increase and form factors shrink, heat concentration becomes a critical challenge. EW systems are expected to operate in extreme environments, where conventional cooling systems may fail due to their inability to adapt dynamically. This has led to the development of next-generation cooling architectures that are both responsive and adaptive.

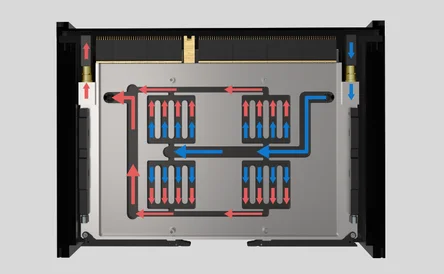

Defense OEMs are now exploring advanced cooling techniques such as liquid cooling and two-phase systems using phase-change materials (PCMs), which absorb and dissipate heat more efficiently than traditional air-based methods. Non-traditional approaches like direct air flow-through (VITA 48.5) and liquid flow-through (VITA 48.4) are also being adopted. These support compact, high-wattage electronics without introducing mechanical noise or vibration that could compromise stealth.

AI in Design and Simulation

AI is revolutionizing the design and development of cooling systems. Traditional thermal modeling is slow and limited by human capacity to explore design variations. AI-driven simulations, however, can evaluate thousands of configurations in minutes, identifying optimal layouts for heat dissipation and airflow.

AI tools enhance computational fluid dynamics (CFD), machine learning, and design algorithms to model heat behavior under varying loads and environmental conditions. This allows engineers to virtually test configurations such as liquid cooling loops, micro-channel structures, or embedded PCMs—without building physical prototypes.

This level of automation not only saves time but also reveals design options that may not be apparent through manual modeling. It improves energy efficiency and extends battery life in portable or unmanned systems. AI can also recommend the most energy-efficient cooling architecture based on specific application needs, helping engineers design solutions with minimal energy consumption.

Safeguarding Electronics

As electronics become smaller, more powerful, and AI-driven, the need for effective thermal dissipation grows. New cooling approaches—including direct air and liquid flow-through techniques—are essential to meet these demands.

nVent SCHROFF is at the forefront of developing modular cooling solutions for advanced electronics in mission-critical environments. Their engineers use advanced simulation and modeling tools to ensure each cooling solution meets customer requirements efficiently. Rigorous testing to international standards ensures reliability across defense, aerospace, communications, and data center applications.

Their portfolio includes Calmark and Birtcher Card-Loks, Wedge-Loks, LHX air-to-liquid heat exchangers, and a range of liquid cooling systems. These technologies are deployed globally to support high-performance electronics in ships, tanks, aircraft, ground control stations, and unmanned vehicles.

Conclusion

AI is reshaping military electronics, pushing conventional cooling systems to their limits. Developers like nVent SCHROFF are rising to the challenge with customized designs and technologies that meet the evolving requirements of defense systems. As EW continues to advance, intelligent thermal management will be key to ensuring operational success and hardware longevity.